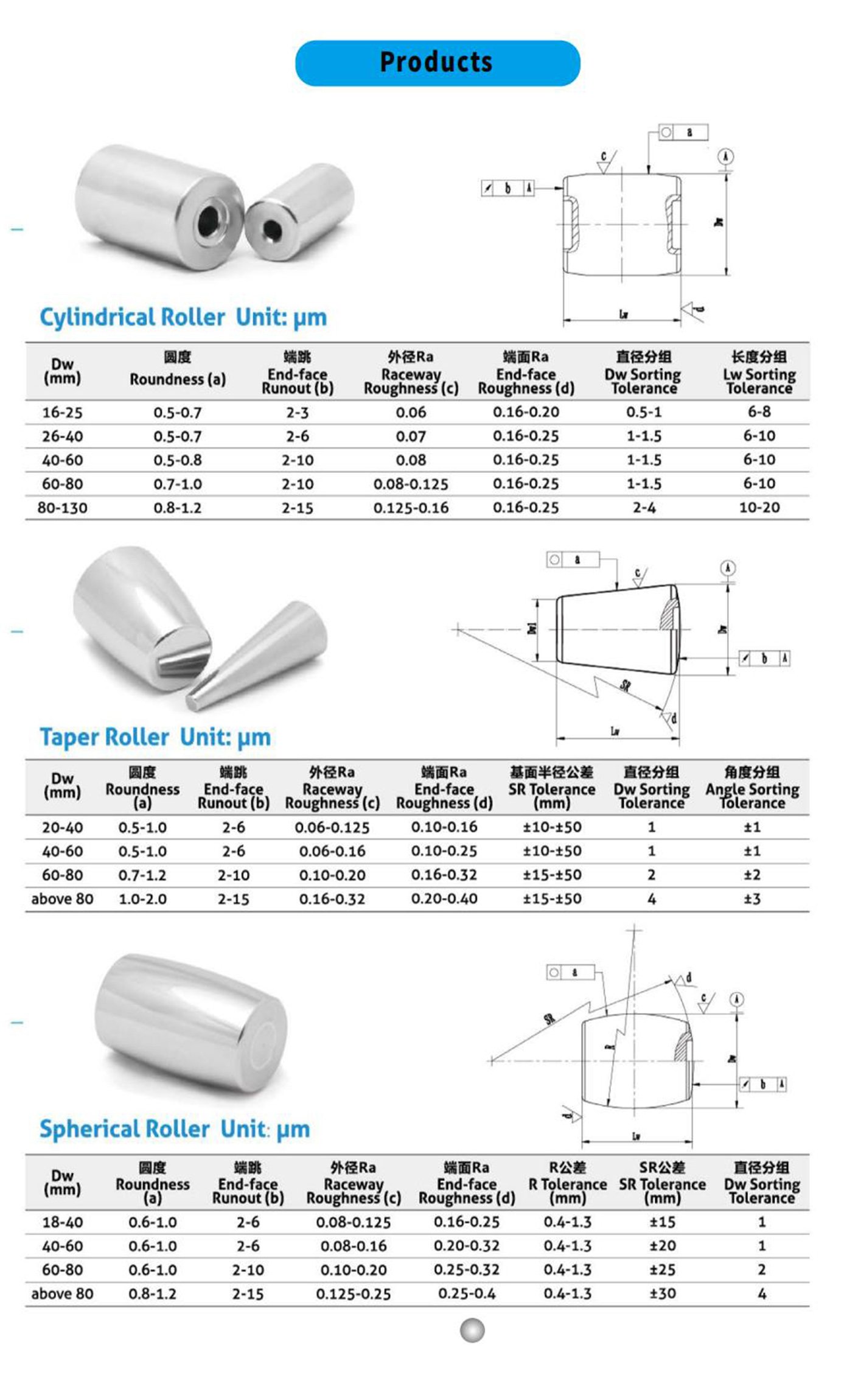

Producs:

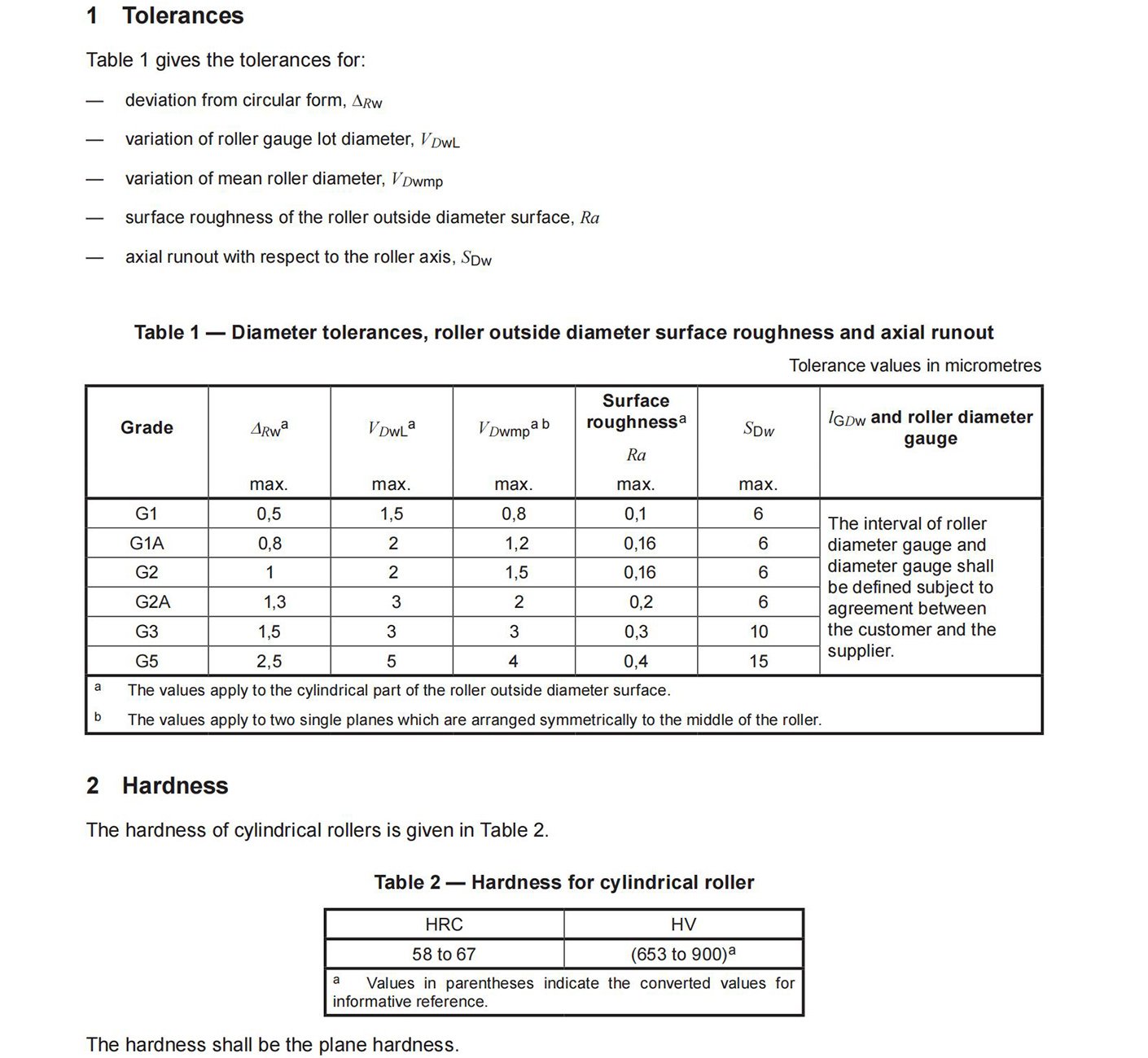

● Cylindrical roller

● Tapered roller

● Spherical roller

Production Range:

● Diameter :1mm-200mm

● Length:3mm-200mm

Quality control:

● Material: UT checking

● Finish rollers:

→ Eddy checking or MPI checking

→ 100% sorting on diameter and length

→ 100% surface checking

Bearing rollers, as the core component of roller bearings, play a crucial role in transmission and support.

With rich experience and reliable resources in the field of rolling elements, EDE has become a leader in the industry.

EDE specialize in providing high-precision cylindrical rollers, tapered rollers, spherical rollers, and needle rollers to meet the needs of different industries and application scenarios.

EDE has extremely high requirements for product quality. We rigorously select raw materials and utilize ultrasonic flaw detection technology to ensure that there are no defects within the material.

During the production process, we strictly control every production step to ensure the stability and reliability of product quality. Finished products also undergo eddy current or magnetic particle inspection to ensure that they are free of potential defects. In addition, we employ advanced sorting technology to precisely sort the length and diameter of the products to ensure accurate dimensions.

In terms of surface treatment, EDE strives for excellence. We adopt 100% camera checking or human visual checking to ensure the smoothness and flawlessness of the product surface. This pursuit of details has made EDE's products highly praised in the market.

EDE's roller products are widely used in various industries such as automobiles, motorcycles, and wind power generation. We are deeply aware of the different demands for rollers in different industries, so we always strive to provide customized solutions for our customers.